It is important that you and your employees follow some strict safety protocols when you use or handle your magnet assemblies.

First, you need to put on gloves and goggles. Gloves are important because they protect your skin from cuts and abrasions, which can otherwise happen if you mishandle the magnet or if the magnet shatters. Goggles protect your eyes from magnet fragments and machining sparks.

Second, if you have a pacemaker, you must never enter the assembly work area. This is because the wholesale magnetic assembly can interfere with or damage any electronic device. Entering the assembly space while using a pacemaker can be fatal, along the same lines, do your best to keep all electronics away from magnets.

Also, if you plan to transport magnets, be aware that they may interfere with the navigation system or stick to magnetic surfaces. To avoid this, take steps to pack your components into isolated containers.

Finally, if you are allergic to metal dust, you should be careful about inhaling it. Wearing a face shield will help stop the inhalation of magnetic dust. If you or one of your employees has a contact allergy, you will need to take further steps, such as wearing protective clothing, or staying out of the area entirely.

Magnets are key components of speakers, speakers and headphones. Different types of magnets produce different ranges of sound quality. Speaker magnet strengths range from 0.001 Tesla to 1.5 Tesla and vary by size and type. The magnets used in headphones are not as strong as those used in speakers. However, stronger speaker magnets must be used to reduce speaker size and have the same strength to produce the desired sound. Here are the different types of magnets used in speakers:

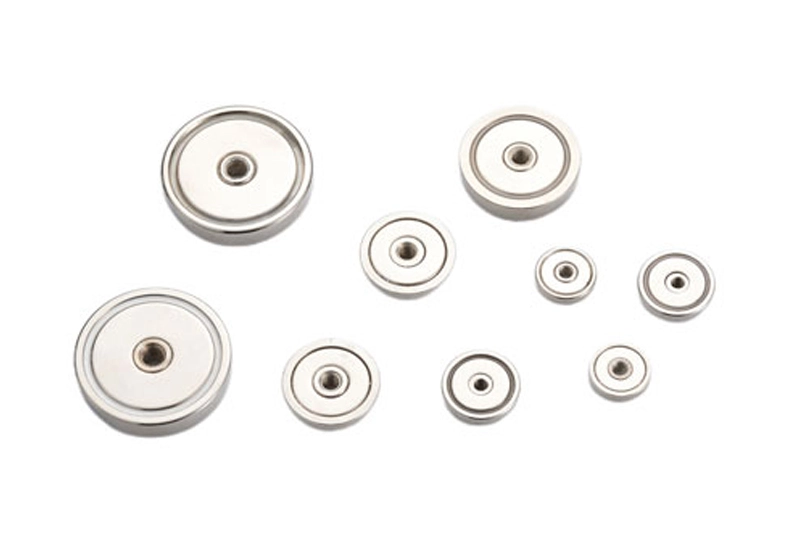

1. Neodymium magnets are the strongest rare earth magnets and can produce good sound when embedded in speakers. Speakers with neodymium magnets have magnet strengths up to 1.5 Tesla. These are typically used in mid to high end headphones. The smaller size of this ultra strong salvage magnet can be used to make smaller speakers because they can pack strong magnetic fields into tiny enclosures. They are best suited for the miniaturization of tweeter drivers, a type of loudspeaker that specializes in producing high frequencies. Most small speaker magnets are at least 0.001 Tesla strong.

Speakers using neodymium magnets have excellent sound quality, better sound elasticity and more accurate frequency response. Furthermore, the robustness of this magnet allows for a good frequency response. Neodymium magnets are considered to provide the most powerful performance. However, their brittleness can lead to cracking when subjected to high impact.

2. Ceramic or ferrite magnets are bulky, making them suitable for large drivers for mid- and high-range woofers and subwoofers. They produce better sound at higher speaker volumes. They are heavy, which adds significantly to the overall weight of the speakers that use them.

They are also corrosion resistant, making them suitable for use in wet environments, such as marine echo sounder applications. Ceramic magnets can maintain their magnetic strength for a long time if there are no stronger magnets around. Compared to the powerful ndfeb magnet, ceramic magnets are less expensive and can be mass produced. Generally, ceramic magnets are favored when long service life and low cost are the main considerations.

3. AlNiCo magnets are alloys of aluminum, iron, nickel and cobalt. They made early permanent magnet drives. As a result, they give the speaker a classic and warm tone. These magnets are known for their tough properties and resistance to cracking. They also have higher heat resistance and are more resistant to corrosion than neodymium magnets.

Because of this, they are more suitable for use in more external applications such as speakers. The main advantage of alnico magnets is that they are easy to magnetize. They can also be easily attenuated, allowing precise tuning for optimal acoustic performance.

Bigger speakers require bigger magnets, but that doesn't mean the overall quality of the sound is just a matter of size. There are other factors at play, such as the audio signal at the speaker level, the heat resistance of the voice coil, the best speaker enclosure, and more. The optimum magnet speaker height to use depends on the purpose of use.

For large speaker cones and subwoofers, large magnets are required to generate cone vibration. For tweeters, high frequencies can be generated very quickly using small magnets. Assuming a constant magnetic field strength, larger magnets can produce louder sounds, while smaller magnets can produce weaker sounds.

High-end speakers use a variety of driver sizes due to differences in frequency response. Larger speakers are better at producing low frequency sounds.

Related Article

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.

Related Products