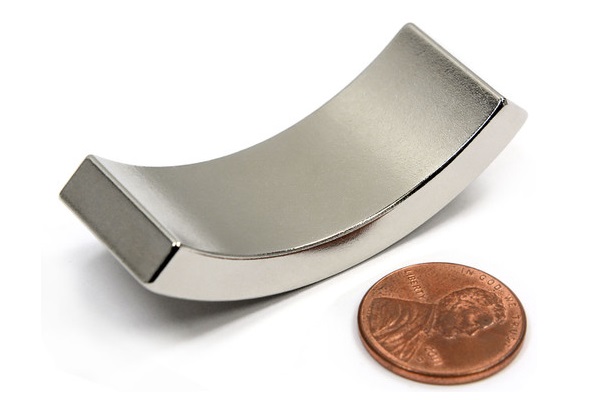

The strong neodymium(NdFeB) magnets in arc/segment shape are mainly used in permanent magnet motor and called neodymium magnetic tile. Strong neodymium(NdFeB) magnetic tile is mainly used in permanent magnet DC motors.

Explore our neodymium arc magnets – tailored for your needs, these powerful magnets deliver exceptional performance across various industries.

The large neodymium arc magnet is a common and powerful magnetic material, known for its high magnetic energy product and excellent corrosion resistance. However, its surface is prone to oxidation, moisture, and wear, which can impact its longevity and performance stability. To address this, surface treatments are employed to enhance its lifespan and stability.

Surface treatments for neodymium arc magnets primarily include methods such as coating, painting, and heat treatment. Among these, coating is a common and effective surface treatment approach. Common coating materials include nickel, zinc, copper, and others. The coating serves to increase the arc magnet's corrosion resistance, preventing oxidation and moisture erosion, thereby extending its magnetic life.

Surface | Coating | Thickness (Microns) | Color | Resistance |

Passivation | 1 | Silver Grey | Temporary Protection | |

Nickel | Ni+Ni | 10-20 | Bright Silver | Excellent Against Humidity |

Ni+Cu+Ni | Good Against Salt Spray | |||

Zinc | Zn | 8-20 | Bright Blue | Excellent Against Salt Spray |

C-Zn | Shinny Color | Superior Against Humidity | ||

Tin | Ni+Cu+Sn | 15-20 | Silver | Superior Against Humidity |

Silver | Ni+Cu+Ag | 10-20 | Silver | Superior Against Humidity |

Gold | Ni+Cu+Au | 10-20 | Gold | Temporary Protection |

Copper | Ni+Cu | 10-20 | Gold | Excellent Against Humidity&Salt Spray |

Epoxy | Epoxy | 15-25 | Black,Red,Grey | Excellent Against Humidity,Salt Spray,Superior Against Solvents,Gases, Fungi and Bacteria,FDA Approved |

Ni+Cu+Epoxy | Excellent Against Humidity | |||

Zn+Epoxy | ||||

Parylene | Parylene | 5-20 | Grey | Excellent Against Humidity |

Chemical | Ni | 10-20 | Silver Grey | Excellent Against Humidity |

Magnetization Direction of Strong Neodymium Ndfeb Arc Magnets

Magnetization Direction of Strong Neodymium Ndfeb Arc MagnetsThe magnetization direction of Neodymium NdFeB arc magnets is a crucial aspect of their design and application. Proper orientation ensures optimal performance in various devices. Engineers carefully align the magnetic domains during manufacturing to enhance the magnets' efficiency and effectiveness in specific applications, such as motors and sensors.

Custom Strong Large Neodymium Arc Magnets

Custom Strong Large Neodymium Arc MagnetsOur custom strong neodymium arc magnets service offers tailored solutions to meet unique magnetic requirements. We provide precise specifications in terms of dimensions, grades, and coatings, ensuring optimal performance for diverse applications. Our experienced team collaborates closely with clients to deliver customized magnetic solutions that match specific design and functional needs, offering reliability and efficiency in various industries.

Neodymium Material Grade | Maximum Working Temp. | Curie Temp. |

N(N35,N38,N40,N42,N45,N48,N50,N52) | 176°F (80°C) | 590°F (310°C) |

N-M(N35M,N38M,N40M,N42M,N45M,N48M,N50M,N52M) | 212°F (100°C) | 644°F (340°C) |

N-H(N35H,N38H,N40H,N42H,N45H,N48H,N50H) | 248°F (120°C) | 644°F (340°C) |

N-SH(N35SH,N38SH,N40H,N42SH,N45SH,N48SH) | 302°F (150°C) | 644°F (340°C) |

N-UH(N28UH,N30UH,N33UH,N35UH,N38UH,N40UH,N42UH) | 356°F (180°C) | 662°F (350°C) |

N-EH(N28EH,N30EH,N33EH,N35EH,N38EH,N40EH) | 392°F (200°C) | 662°F (350°C) |

N-AH(N28AH,N33AH,N35AH,N38AH) | 428°F (230°C) | 662°F (350°C) |

Related Products

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.