Magnets all have two poles, but in some working positions, a single-sided magnet is required, so it is necessary to wrap one magnet with an iron sheet, so that the magnetism on the side covered by the iron sheet is shielded, and the magnet on the other side is refracted by the iron sheet. The magnet increases the magnetic force of the magnet on the other side. Such magnets are collectively referred to as single-sided magnets or single-sided magnets, and there is no real single-sided magnet.

The difference: the single-sided magnet has strong magnetism on one side and weak magnetism on the other side, but it does not mean that there is no magnetism. Double-sided magnets are magnetically equivalent in both directions.

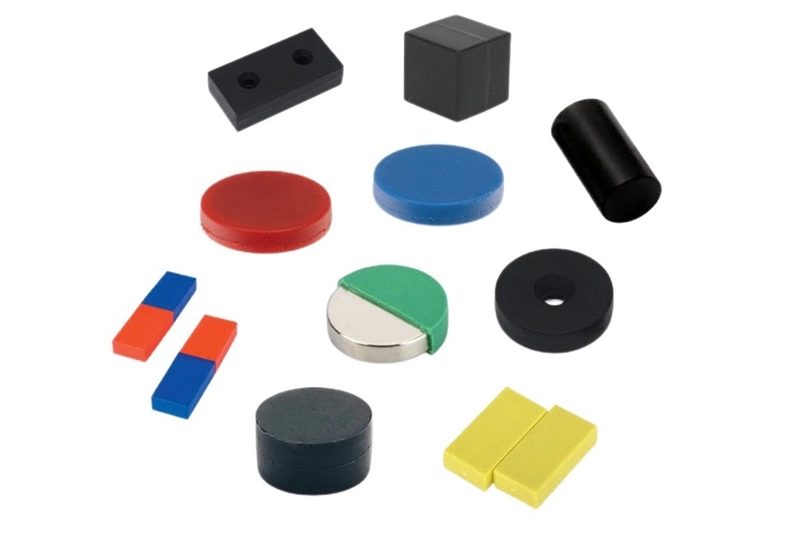

The material used for single-sided magnets is generally arc-shaped iron sheets, and the shape of powerful magnets used for single-sided magnets is generally circular.

1. It is widely used in the printed matter industry. There are single-sided magnets in gift packaging boxes, mobile phone packaging boxes, tobacco and alcohol packaging boxes, mobile phone packaging boxes, MP3 packaging boxes and other products.

2. It is widely used in the leather goods industry. There are single-sided magnets in leather goods such as luggage, briefcases, travel bags, mobile phone sets, and wallets.

3. It is widely used in the stationery industry. Notebooks, whiteboard buttons, folders, magnetic nameplates, etc. all have single-sided magnets.

The permanent magnet material is a permanent magnet material based on the intermetallic compound NdFeB. NdFeB has a very high magnetic energy product and coercive force, and at the same time, the advantages of high energy density make NdFeB permanent magnet materials widely used in modern industry and electronic technology, thus making instruments, electroacoustic motors, magnetic separation magnetization It is possible to reduce the size, weight, and thickness of other equipment.

Material characteristics: NdFeB has the advantages of high cost performance and good mechanical properties; the disadvantage is that the Curie temperature point is low, the temperature characteristics are poor, and it is easy to be pulverized and corroded. It must be adjusted by adjusting its chemical composition and adopting surface treatment methods. It can be improved in order to meet the requirements of practical application.

1. Appearance: ferrite is loose and has no metallic luster, generally not electroplated, usually black. NdFeB is basically electroplated, otherwise it is easy to rust. The surface has silver-white metallic luster.

2. Magnetic force: According to the information, the magnetic force of ferrite is usually 800-1000 Gauss, and the density is 5 (g/cm3 ). In the state of bare magnetism, the NdFeB magnetic force can reach about 3500 Gauss. The density was 7.5 (g/cm3 ).

3. In terms of performance: ferrite has good temperature resistance and stability. In contrast, the normal temperature resistance of NdFeB is only 80℃. And the price is also cheap. NdFeB has the characteristics of small size, light weight and strong magnetism, and the magnetism is completely different from that of ferrite.

4. In terms of price: ferrites are usually cheap, and many are calculated on a piece-by-piece basis. The price has an impact on the shape, size, and processing difficulty of the ferrite. Now the price of NdFeB is changing almost every day, depending on the grades and special requirements that need to be used.

Related Article

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.

Related Products